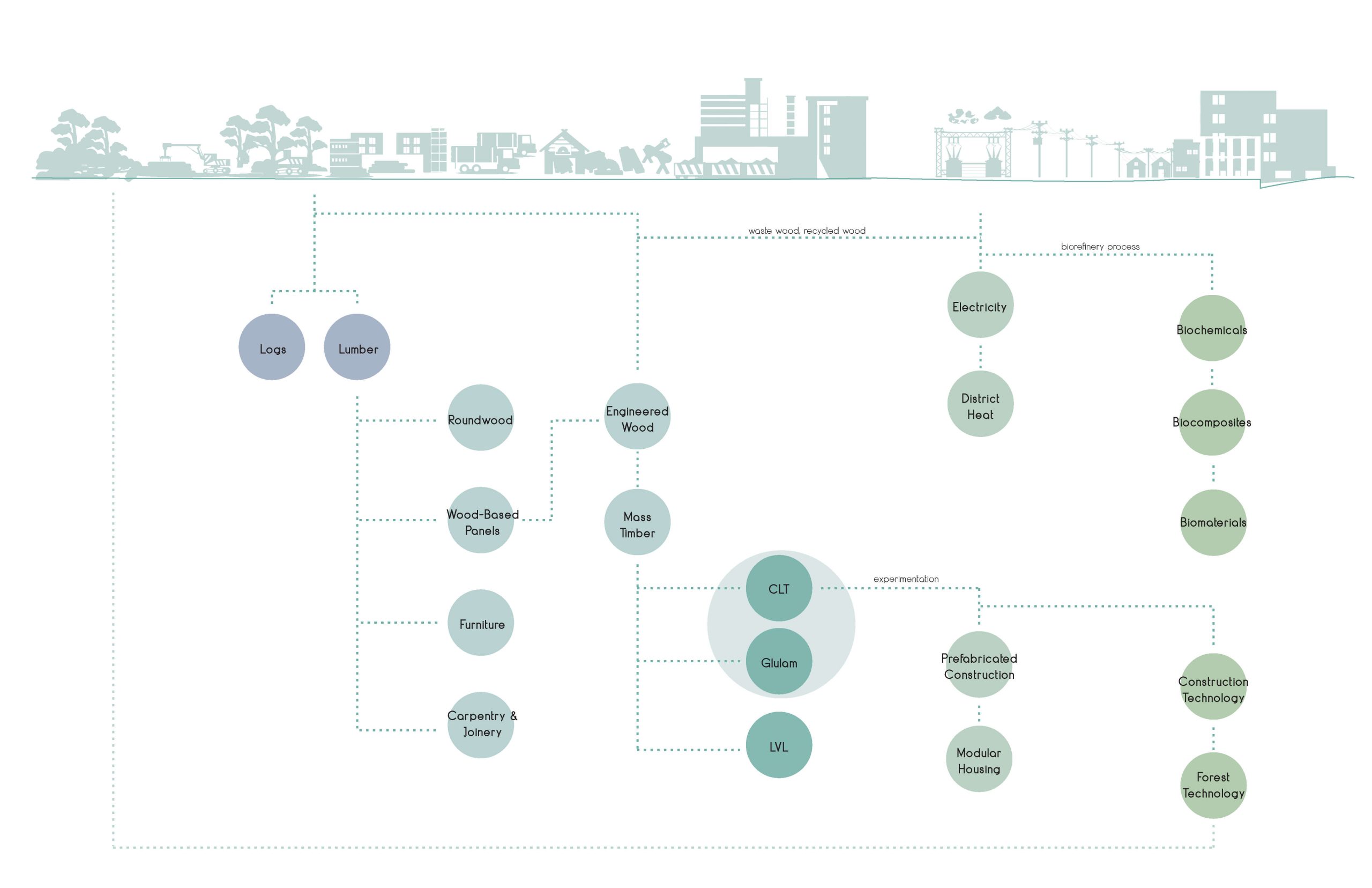

“How can a transition to mass timber be catalytic to a broader cultural change?” This has been the critical question that the thesis seeks to explore throughout the term, along with understanding the potential implications of building with mass timber in the GTHA (Greater Toronto and Hamilton Area) region and the potential growth in the forest industry in supplying wood-related construction materials. Carbon impact, new technologies, and policy changes have significantly influenced the potential growth in the mass timber industry, however, supply chain gaps, distribution challenges, building code compliance and cost still remain to be the prominent barriers in the current industry.

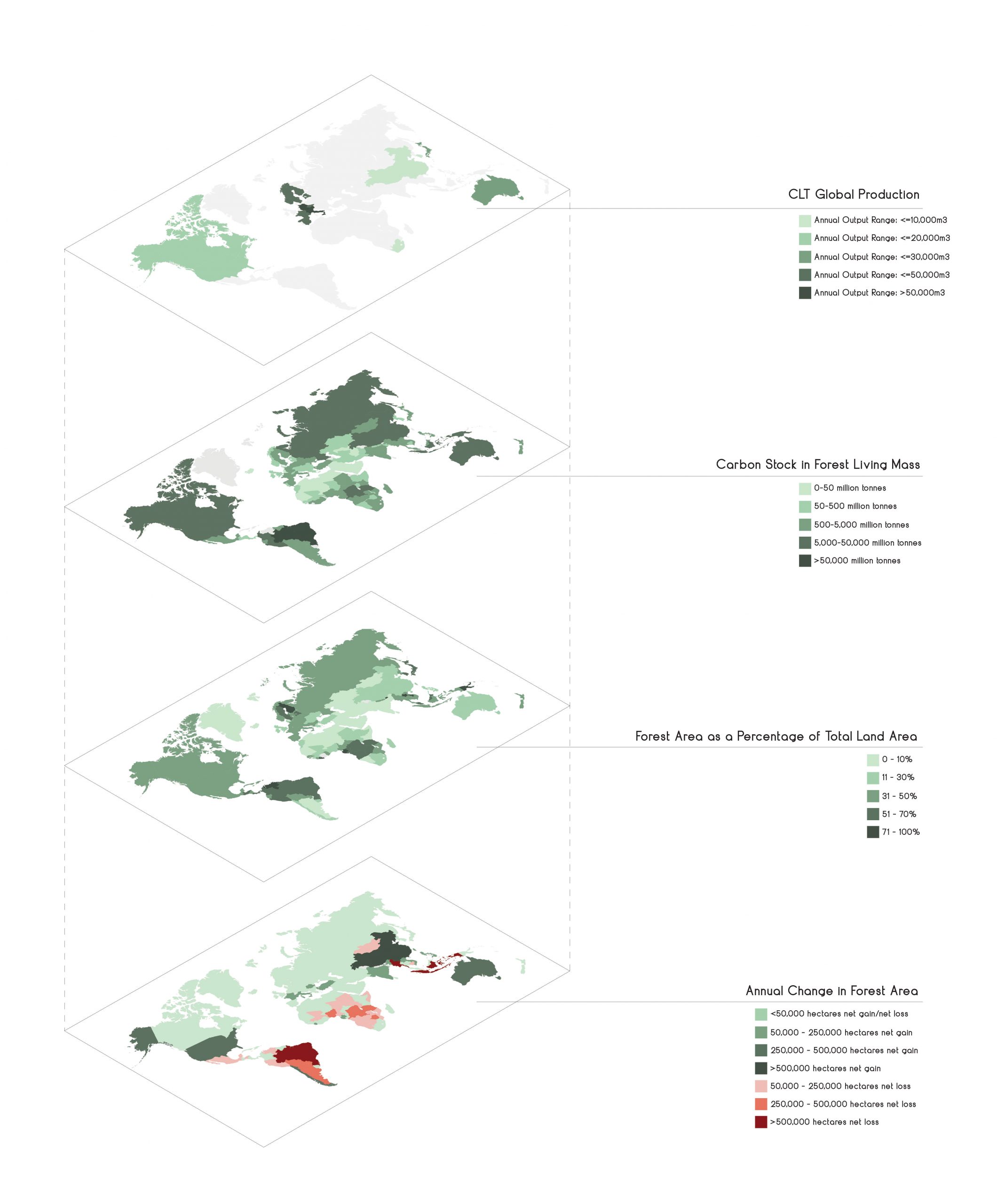

As long ago as 2001, the United Nations Food and Agriculture Organization (UNFAO) determined that in region such as Canada, loss of forest cover is no longer a quantitative issue. In parts of Europe, the United States and Canada, the area of forests is actually increasing, with North America now approaching the level of forest cover it had when the first European settlers arrived in the early 17th century.

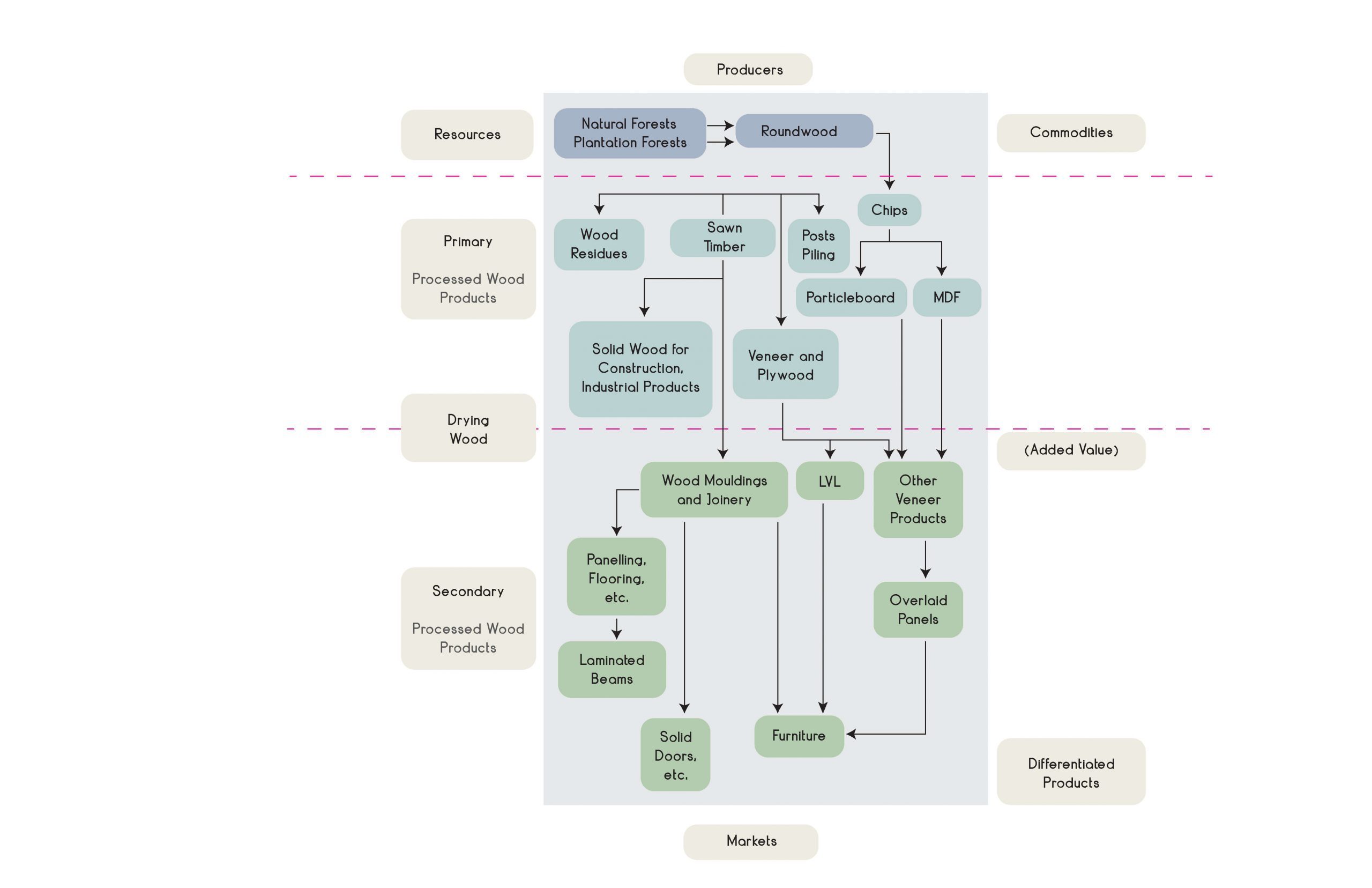

In terms of the forestry industry, the increase of mass timber construction can be beneficial for the forestry sector, as the increased demand for the forest products can spur economic development and investment in the mass timber supply chain. In a way, mass timber construction can help to deplete our forests, by harvesting trees when they reach maturity, the trees and the carbon that they store can be transformed into a resilient building material, and the forest can be regenerated with new trees which can capture greater amounts of carbon and to further perpetuate the cycle.

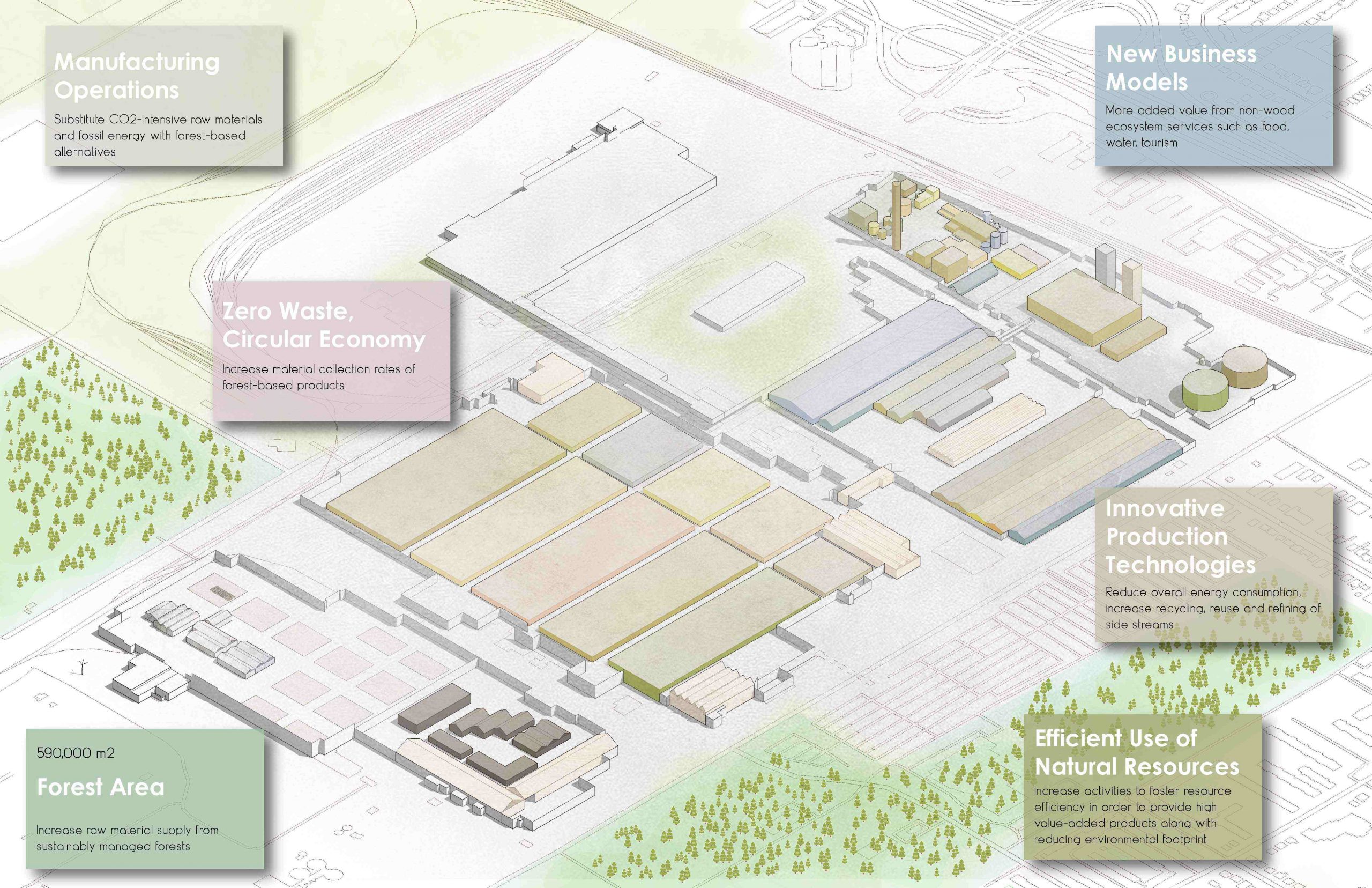

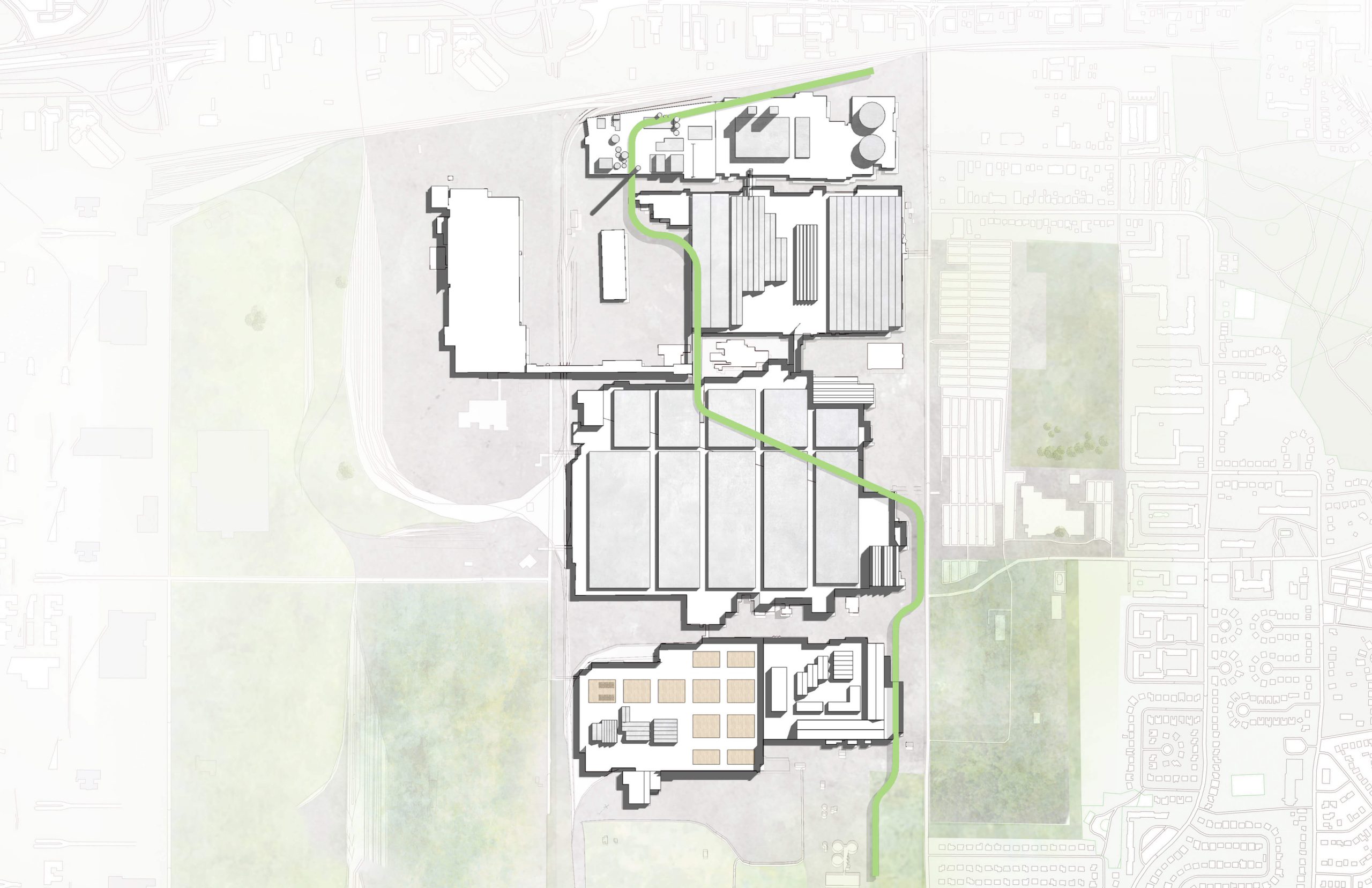

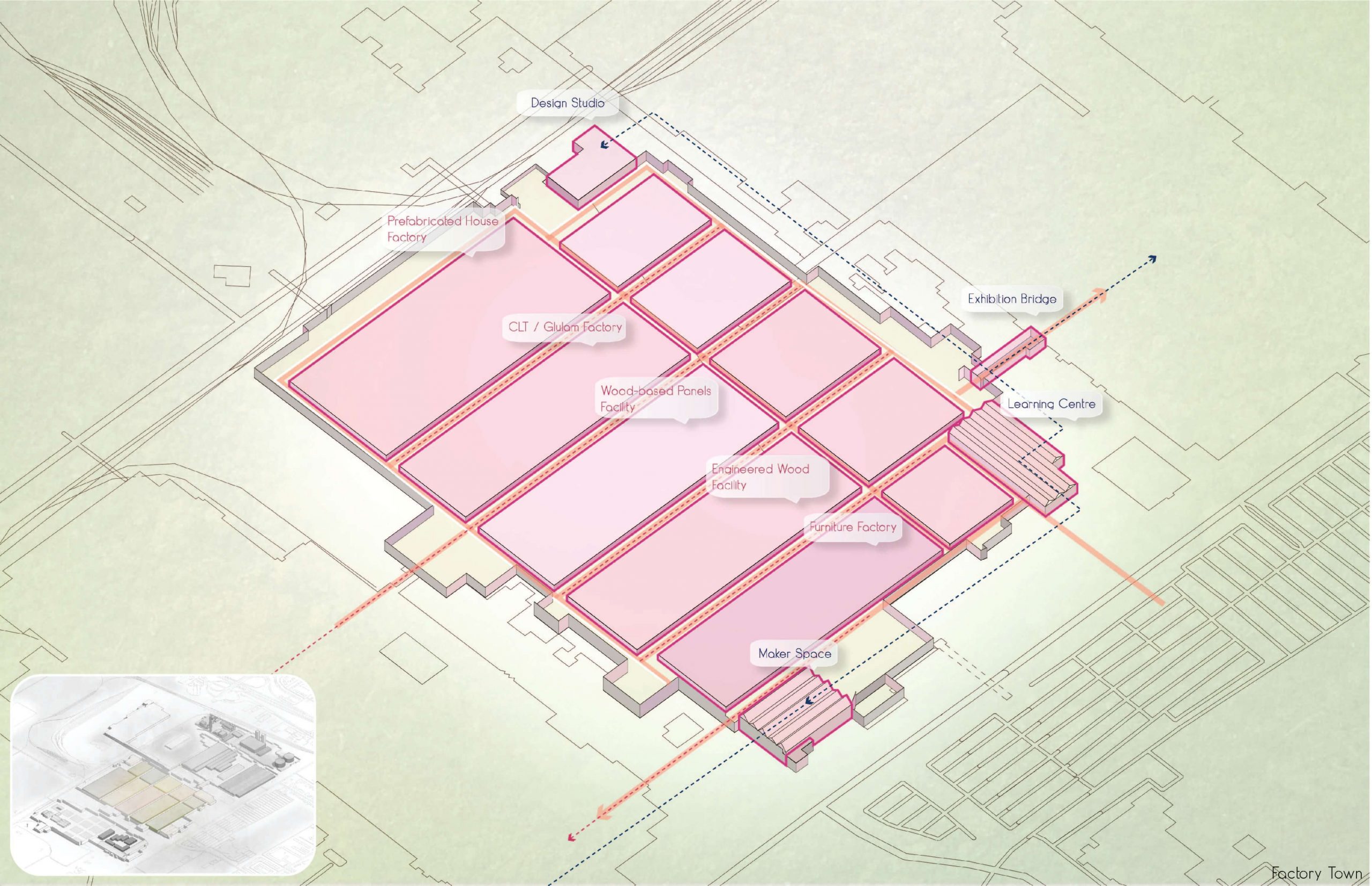

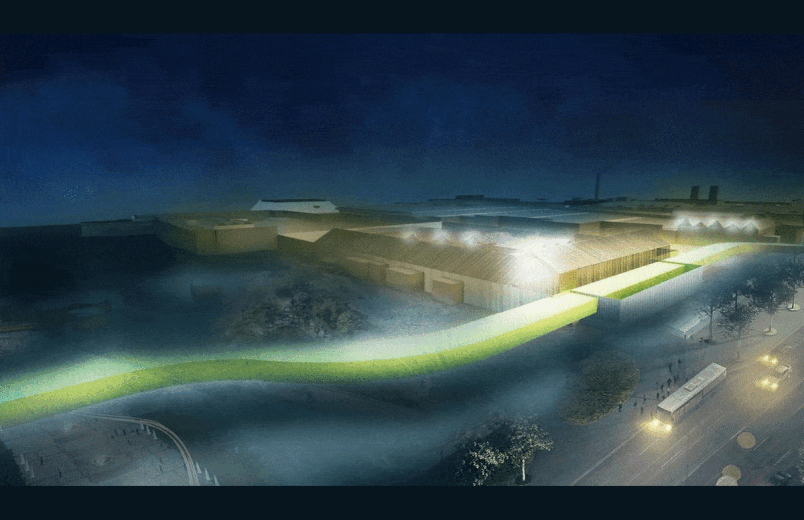

With regards to establish a new mass timber supply chain, the General Motors (GM) assembly plant located in Oshawa has been selected as a potential site. The goal of the design aims to provide an industrial park that can help to maximize the mass timber production with more products, higher quality, and economic outcome, as well as to provide educational opportunities to the general public and individuals in the AEC industry on sustainable development and mass timber construction. In addition, the intent is to limit the use of resources in an environmentally sustainable manner, along with creating a cost effective working environment.

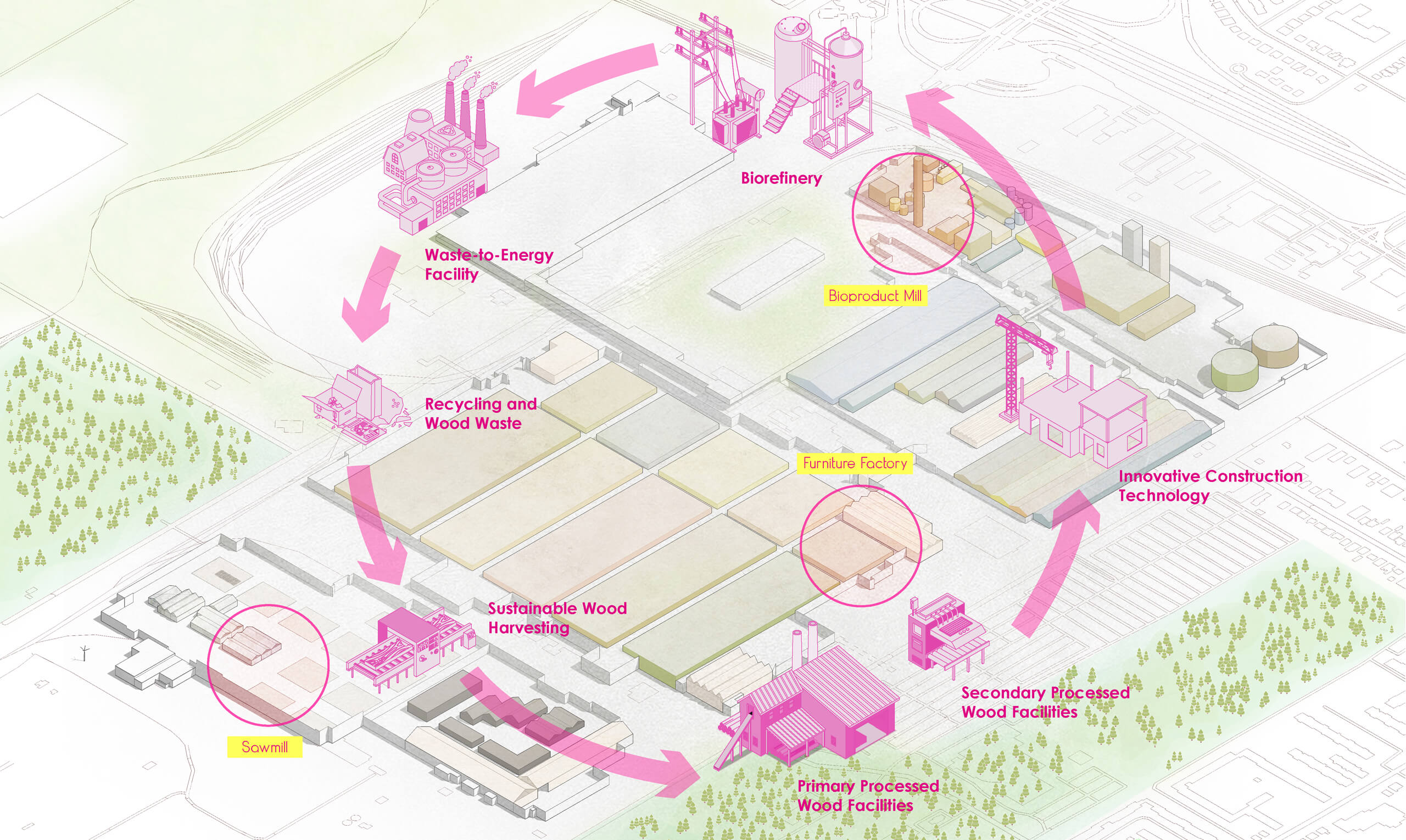

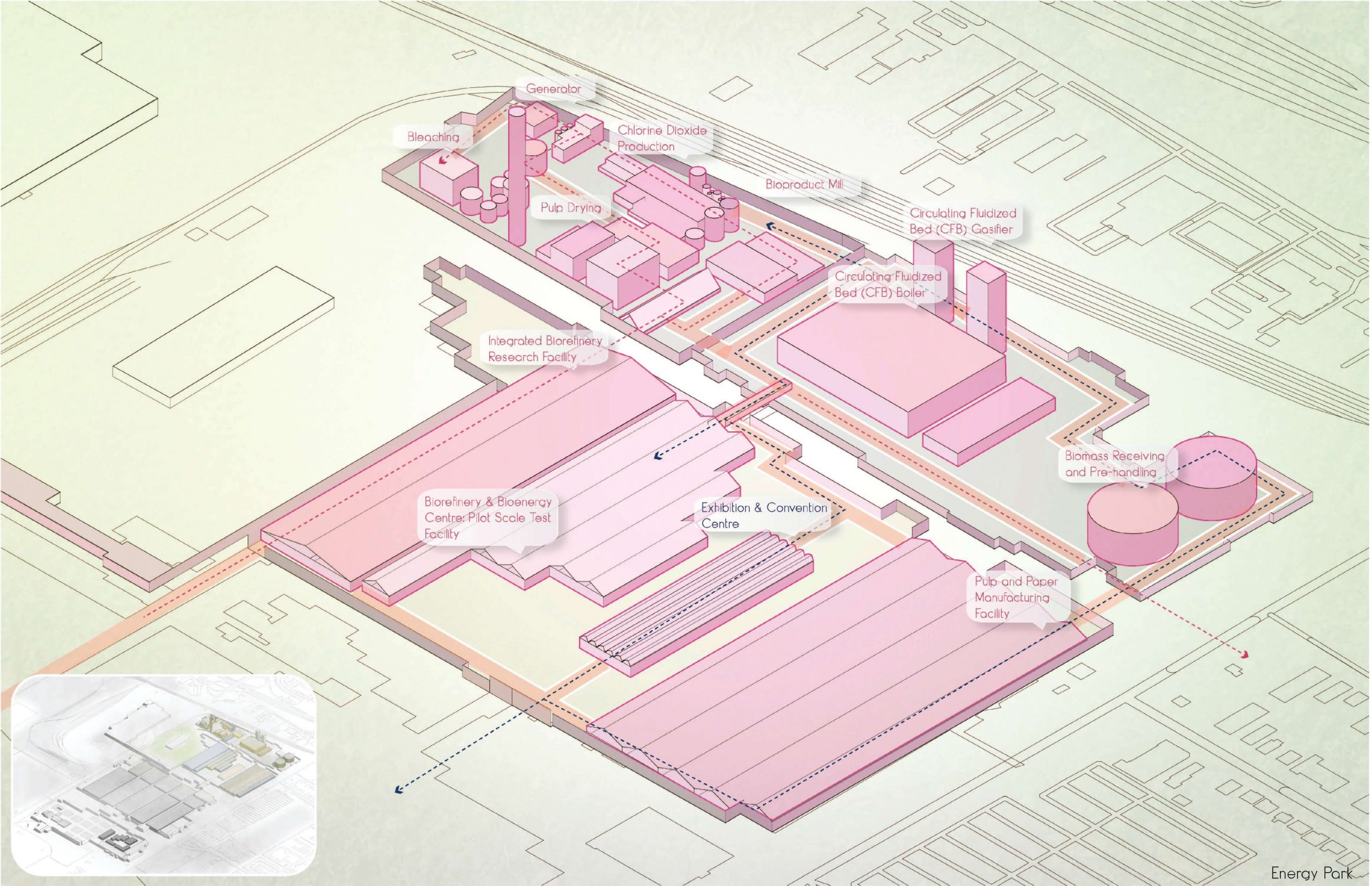

The main products that would come out of the industrial park include bioproduct, bioenergy, and mass timber products. Sustainable and efficient use of bioenergy can play an integral role in low-carbon scenarios. Bioproducts can be used to mitigate greenhouse gas emissions in many sectors that have few alternative options. The self-sustained facility will combine a variety of advanced technologies with recreational, education, and ecological features.

Proposed industrial park located in Oshawa: Transformation of the automobile industry into a mass timber industry

The manufacturing process layout has been divided into three major zones: a high-tech zone with an innovation district, an industrial district that consists primarily of manufacturing operations, and an energy park that comprises of a large waste-to-energy facility.

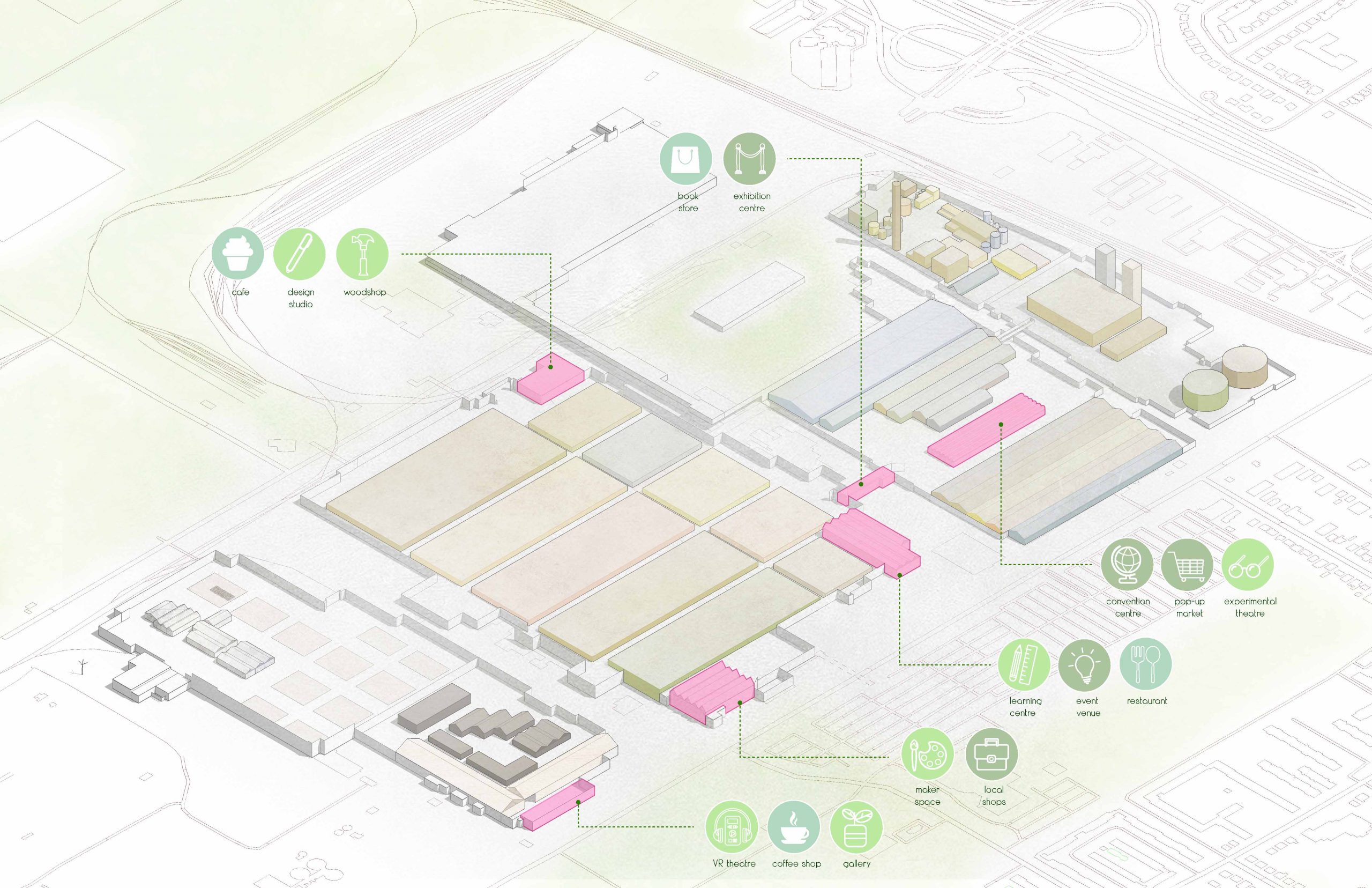

Apart from the industrial manufacturing operations, there are also a series of cultural attractions, such as a convention centre, an exhibition area, and a learning centre. The design intent aims to develop small scale typology within the industrial park to encourage interaction within different sectors along with bridging the gap between the academic research and industrial manufacturing.

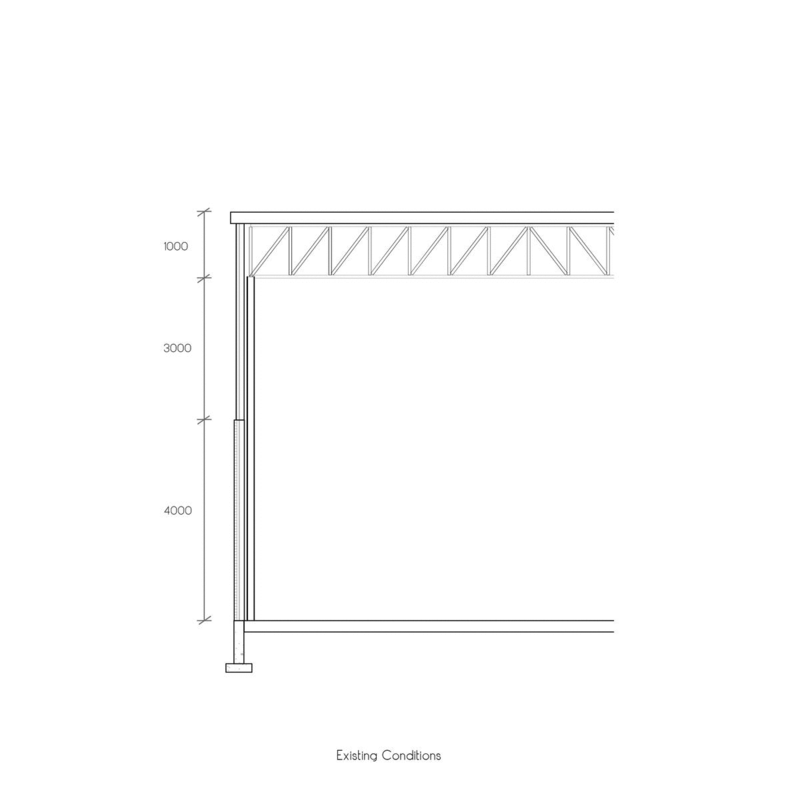

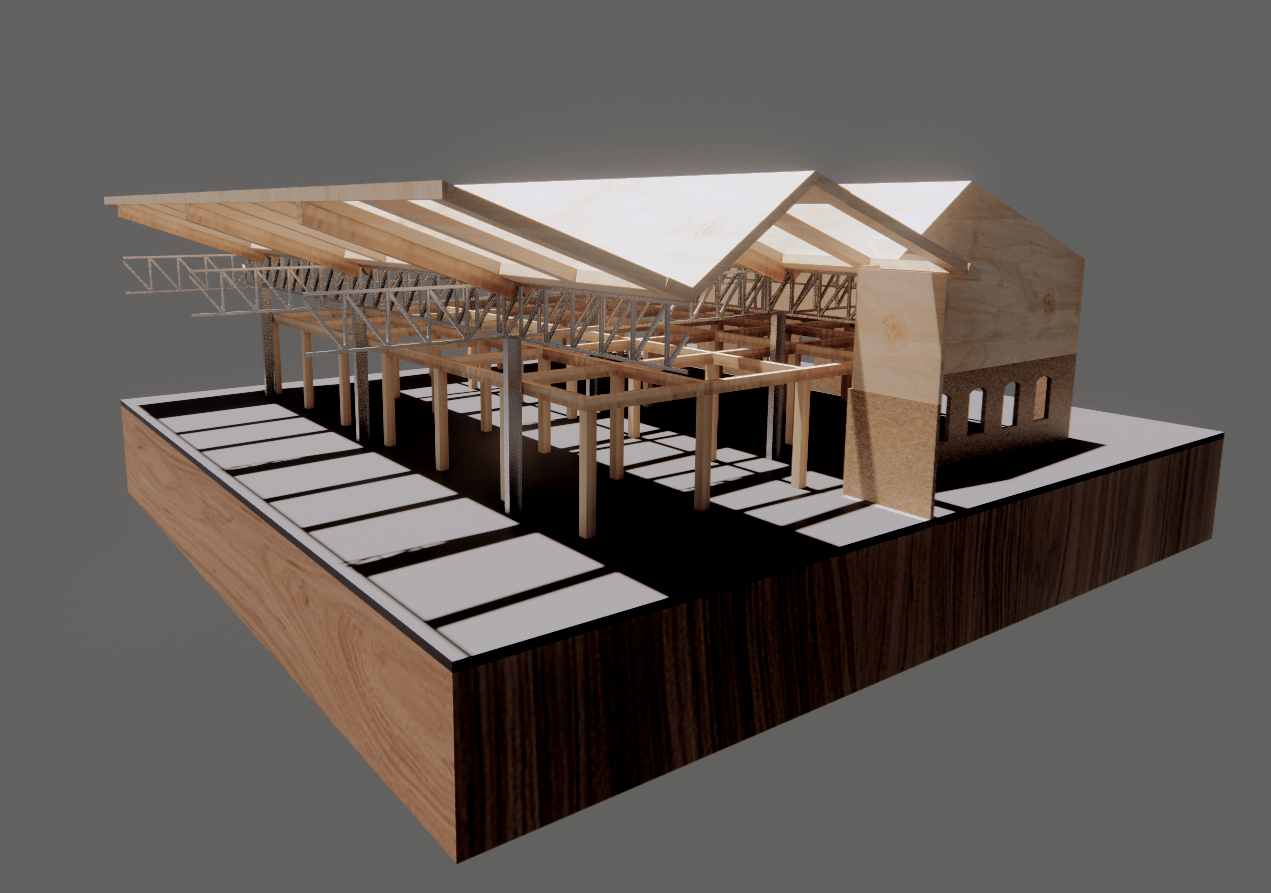

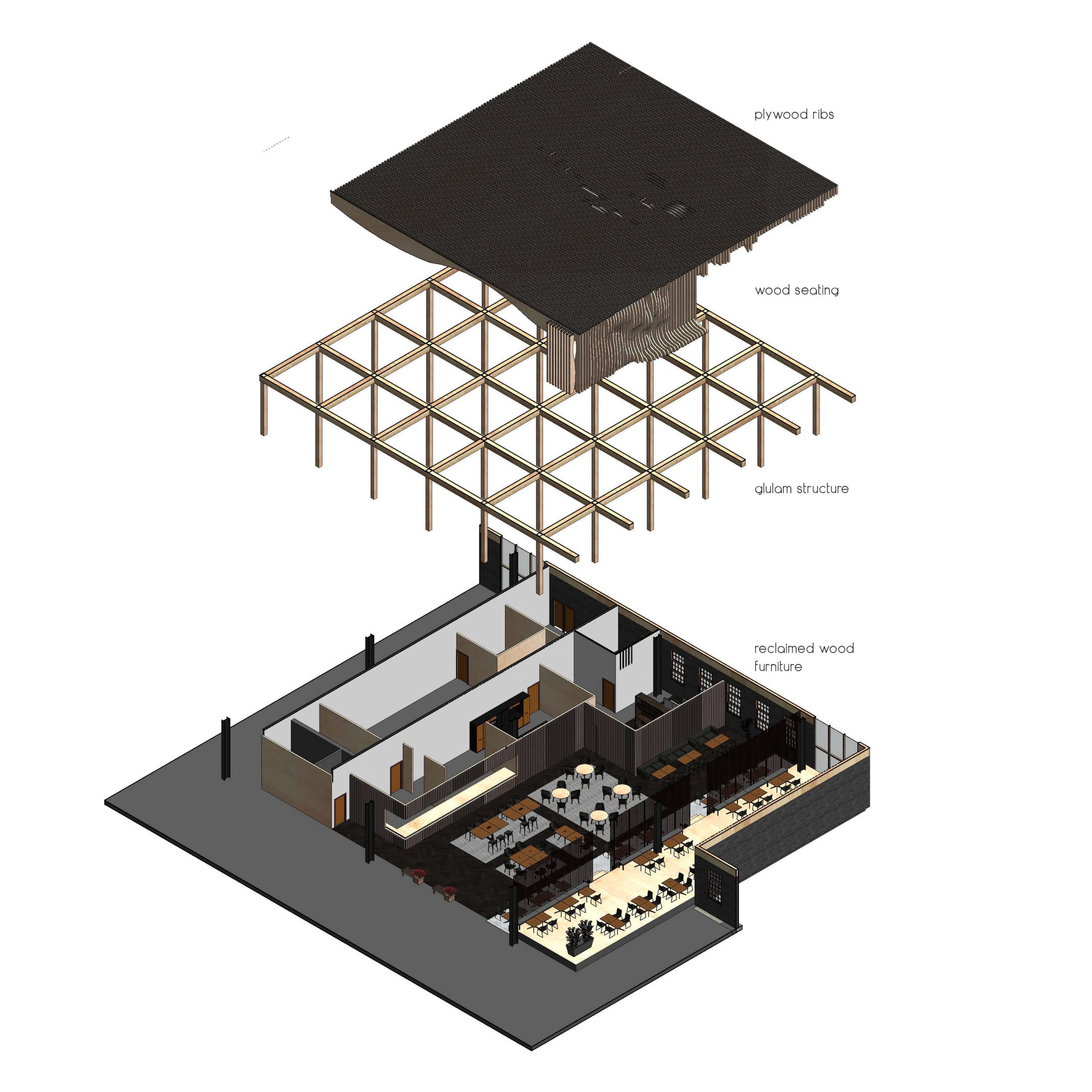

New public recreational programs will be integrated into the industrial park through retrofitting the existing buildings.

For instance, a factory café is integrated into the complex to establish an urban leisure place, and to advocate environmental sustainability by utilizing the wood products manufactured from the on-site manufacturing facilities.

Essentially, the design proposal aims to decarbonize GTHA by substituting carbon intensive raw materials and fossil energy with forest based alternatives as well as to ensure primary raw materials are supplied from sustainably managed forests. In addition, the circular bioeconomy aims to contribute to a zero-waste economy by processing waste and side-streams into circular added-value products.