Equipments

- Lab Co-Rotation Twin Screw Extruder

- Onyx IM-380 Injection Molding Machine

- Onyx Co-Rotation Twin Screw Extruder Compounding and Sheet Line

Resources

Lab Co-Rotation Twin Screw Extruder

Suitable for compounding polymers with different additives, bio-material based filler or mineral fillers.

| Model | Onyx TEC-25/40 |

| Throughput capacity (kg/hr) | 2 ~ 15 kg |

| Screw diameter | 25 mm |

| L/D ratio | 40 |

| Main motor power | 5.5 kw |

| # of volatile venting port | 3 |

| Type of pelletizing | Strand die |

- Co-Rotation Twin Screw Extruder

Onyx IM-380 Injection Molding Machine

Standard, full size industry injection molding machine for making parts weighing up to 1.1kg.

| Model | Onyx IM-380 |

| Shot weight | 1115 g |

| Screw diameter | 70 mm |

| L/D ratio | 20 |

| Injection pressure | 1698 kg/cm2 |

| Clamping force | 380 ton |

| Distance between tie bars | 740 X 740 mm |

| Max daylight | 1450 mm |

| Mould thickness range | 250 ~ 740 mm |

| Main motor power | 50 hp |

- Injection Molding Machine

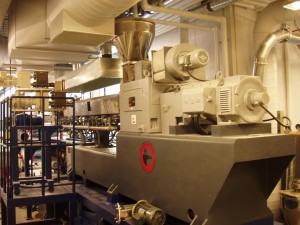

Onyx Co-Rotation Twin Screw Extruder Compounding and Sheet Line

The system is designed for compounding bio-composite and bio-material. The complete compounding line is consisted of :

(1) one 65 mm Co-Rotation Parallel Twin-Screw Extruder for compounding polymer and additives or fillers;

(2) one die face cutting pelletizing line to transfer the melt into pellet;

(3) one 120 mm single extruder to convey the melt from up twin-screw extruder into the sheet or profile die to make end products;

(4) one 3-roller calender sheet line to make 20 inch wider polymer composite sheet with wide range of thickness.

Both the screw and barrel of the twin-screw extruders were designed using the building block principle. The screw configuration, barrel setup, screw L/D, number of feeding & venting protocols, screen changes, granulating methods and electrical controls are optimally adjusted according to the material properties and process requirements. The closely intermeshed screw elements have excellent self-wiping characteristics, and can be easily interchanged with others.

| Model | Onyx TEC 65/44 |

| Screw diameter | 65 mm |

| L/D ratio | 44 |

| Max. screw rpm | 600 |

| Main motor power | 55 kw |

| # of volatile venting port | 3 |

| Die | Circular die |

| Pellet cooling system | Air |

| Throughput | 250 kg/hour |

- 65mm Twin-Screw Extruder

| Model | SE120 |

| Screw diameter | 120 mm |

| L/D ratio | 9 |

| Max. screw rpm | 65 |

| Main motor power | 30 kw |

| Die | Sheet or profile die |

| Throughput | 250 kg/hour |

- 120mm Single Extruder

| Roll Diameter | 35 (mm) |

| Roll Length | 700 mm |

| Sheet Width | Up to 450 mm |

| Sheet Thickness | 0.6 mm ~ 2 mm |

- 3-Roller Calender Sheet Line