WHAT IS MASS TIMBER?

MASS TIMBER IS AN ENGINEERED, WOOD-BASED STRUCTURAL BUILDING MATERIAL SUITABLE FOR LARGE-SCALE INFRASTRUCTURE PROJECTS SUCH AS BUILDINGS AND BRIDGES.

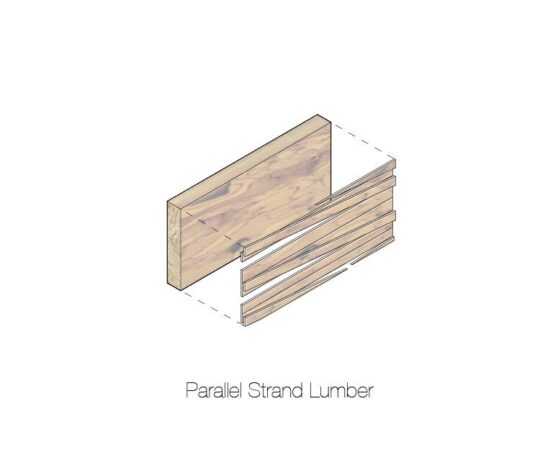

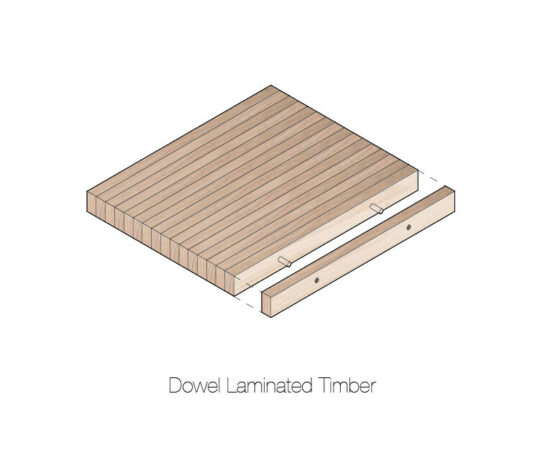

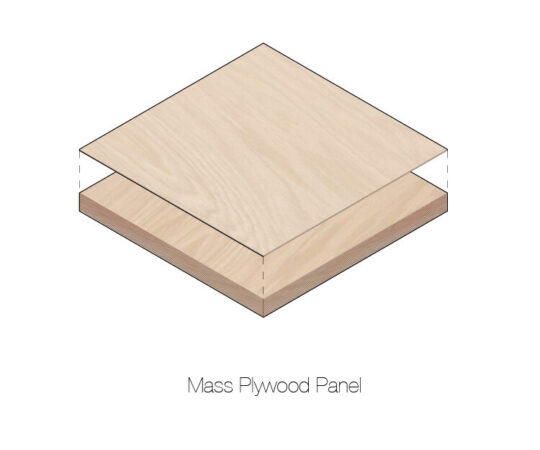

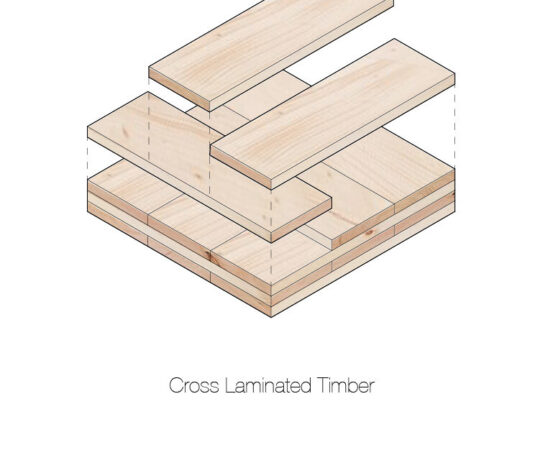

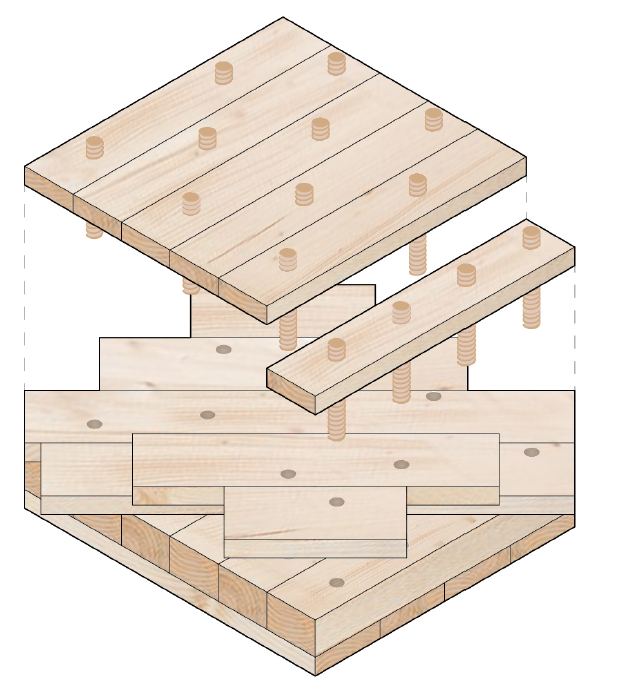

There are several important types of mass timber products, including cross-laminated timber (CLT), glued laminated timber (glulam), nail-laminated timber (NLT), dowel-laminated timber (DLT), mass plywood panels (MPP), laminated veneer lumber (LVL), parallel strand lumber (PSL), and laminated strand lumber (LSL). Want to learn more? Check out our information bulletin on the topic below. Diagrams by Sanjana Patel, Mass Timber Institute. If you would like to use our diagrams in your own work, send us an email!

OUR INFORMATION BULLETINS

Our information bulletins provide “bite-sized” and accessible information to readers that would otherwise need to access the larger technical and scientific literature on mass timber technologies and building systems. The purpose of these bulletins is to “connect the dots” in terms of published results that can be accessed by the broad diversity of interests in the mass timber sector. Click on a bulletin to download a copy.

FIRE AND MASS TIMBER

Did you know that the steel connections can actually fail before the wood in a fire? Click below to learn more!

Download – Fire

CARBON AND MASS TIMBER

Curious about embodied carbon or the environmental performance of mass timber? Click below to find out more!

Download – Carbon

MASS TIMBER AND SOCIETAL WELLBEING

Did you know that exposed wood can be calming, improve eyesight, and reduce insomnia? Click below to learn more!

Download – Societal Wellbeing

WHAT IS MASS TIMBER?

Want to learn more about the different mass timber products or how they are made? Click below to read more!

Download – Mass Timber

MASS TIMBER CONNECTORS

Although connectors are relatively small in size, their detailing is key to a good mass timber structure. Click below to read more!

Download – Connectors

MASS TIMBER ADHESIVES

Adhesives laminate layers of wood together to create mass timber products. Adhesives are selected for appearance, cost, and various other standards they meet to ensure the quality of the finished product. Click below to read more!

Download – Adhesives

ADHESIVE FREE WOOD JOINING

An overview of adhesive free joining techniques with Mass Timber products. Click below to read more!

Download – Adhesive Free Wood Joining

Bulletin Images: Cullan Smith, Ian Keefe, Jared Rice, Aaron Burson on Unsplash

Banner rendering: DIALOG