Research and education are key components of our mission. Here we showcase some work done by students associated with the Institute.

Accounting for Time in Life Cycle Assessment: Case Study of a Mass Timber Building

By: Lihan Jin• 2022

Due to the rising popularity of mass timber buildings, it is crucial to critically examine the impact that wooden construction has on the climate. Unfortunately, the climate impact of wood is highly contested due to a knowledge gap in how to account for time in life-cycle assessment (LCA). The traditional LCA approach of giving equal weight to time is unreasonable because in general, the climate impact of a carbon flow depends on its time of occurrence. This thesis proposes an ‘advanced’ LCA method that incorporates the dimension of time. The proposed method employs the absolute global temperature change potential (AGTP), and uses simple emission functions to model the emission profiles of buildings. A sensitivity analysis conducted using the proposed method discovered that the AGTP of a mass timber building both depends on the rotation period of the forest stand from which raw materials were extracted, and on the assessment time horizon. It highlights the need for advanced LCA methods by showing the inability of traditional LCA to capture the natural evolution of climate impacts over time. Overall, due to its simplicity, this thesis recommends the proposed method for inclusion in LCA standards and for use by building designers to compare the climate impacts of material and design decisions at the early stages of a building project. It is hoped that future research will further the standardization of an LCA method that accounts for time, and create a more complete understanding of the climate implications of the shift to mass timber.

A STUDY ON THE FEASIBILITY OF CONDUCTING LAMINATED VENEER LUMBER PRODUCTION IN THE WHITEFEATHER FOREST IN NORTHWESTERN ONTARIO WITHIN THE LANDS OF THE PEOPLE OF PIKANGIKUM

By: Feiran Xu • 2021

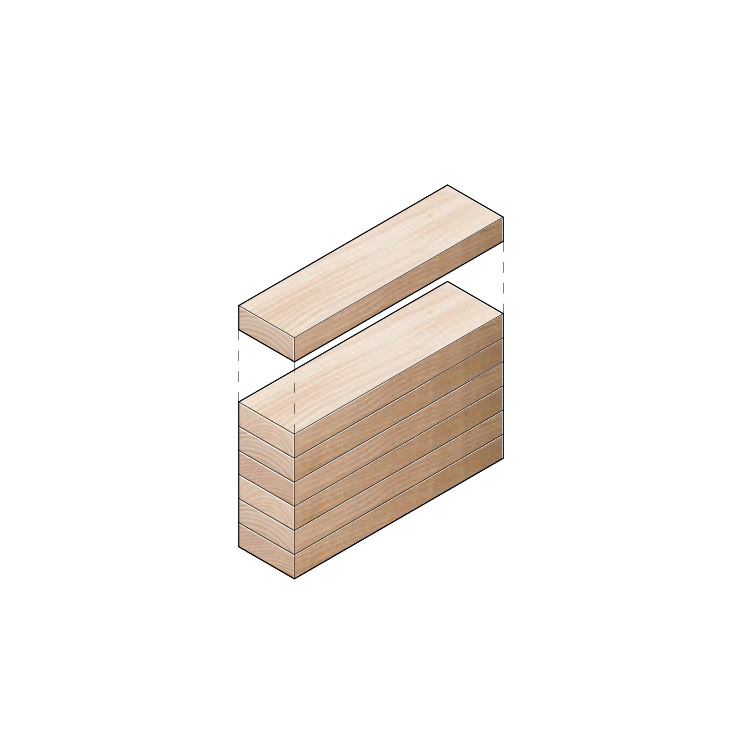

Mass timber is an umbrella concept that refers to the large engineered wooden panels, columns, and beams that have been widely recognized as viable alternative to steel and concrete in the construction industry. In addition to the advantages of carbon sequestration, energy savings, fire resistance, and pre-assembly, mass timber offers Indigenous communities, especially those in rural areas like the Pikangikum First Nation in Northern Ontario, an opportunity to provide Indigenous youth training, to find a pathway for businesses in the community, to gain tax revenue, and to compete with the ordinary Canadian communities and their low-value commodity products such as pulp and softwood lumber. A BBC (Banker, Charnes, and Cooper) model in data envelopment analysis (DEA) is used to measure the technical efficiency of five small-scale Chinese mass timber manufacturers during 2012-2018, and a cost-benefit analysis (CBA) is used to analyze the feasibility of investing in a laminated veneer lumber (LVL) production line in the Pikangikum community. The technical efficiency results show that mass timber production technology is effective, mature, and can be imported. It is estimated to cost US$ 8.8 million and 33 people to set up the LVL production line with an annual output of 30,000 m3. The estimated net sales margin is 18.87%, payback in 5 years, and the 12-year internal rate of return (IRR) is 23%. In conclusion, conducting laminated veneer lumber production in the Whitefeather Forest in Northwestern Ontario within the lands of the People of Pikangikum is expected to be feasible and profitable.

OUTLOOK FOR MASS TIMBER: A SASKATCHEWAN CASE STUDY

By: Lindsay Dandridge • 2021

Mass timber, an engineered wood product, is an environmentally acclaimed technological development that aims to compete with concrete and steel as the structural component in mid-rise and tall building construction. A feasibility study was conducted to assess the province of Saskatchewan’s forestry sector and its overall potential to support mass timber production and construction. An analysis of publicly available provincial documents and a literature review of mass timber products, building strategies and policies directed a qualitative research approach that informally questioned industry, government and institutional professionals. Document review and industry interviews revealed a surplus in wood supply that could potentially feed mass timber production. Government and education representatives identified a lack of discourse around mass timber. Overall, there is potential to supply mass timber manufacturing, but significant barriers exist that will likely prevent mass timber construction from being implemented in Saskatchewan any time soon.

HARDWOOD CLT PROGRAM IN SOUTHERN AND CENTRAL ONTARIO

By: Xincheng Li • 2021

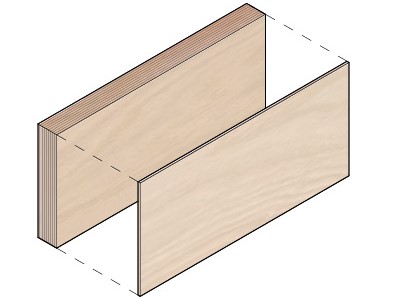

Cross-laminated timber (CLT) is a large prefabricated solid engineering plank made of multiple layers of planks glued together and it is primarily used in structures such as the floors, walls, and roofs of buildings. ANSI/APA PRG 320 is the world recognized CLT lumber production standard, and the main raw material of CLT has always been softwood rather than hardwood. However, the bending strength, compressive strength, and shear strength of hardwood CLT lumber are stronger than softwood CLT lumber. The large and underutilized hardwood resources in central and southern Ontario provide a huge resource advantage for the hardwood CLT project. This article uses the Cost-Benefit Assessments model to assess the feasibility of investing in hardwood CLT plants in central and southern Ontario. The results show that the payback period of the hardwood CLT factory is 5 years, and the rate of return on investment of 10 years, 15 years, and 20 years are all-around 11%. This study could strengthen investor confidence and it also identifies the direction for the development of hardwood CLT plants in central and southern Ontario.

NEST RECONFIGURABLE LVL STRUCTURES FOR NORTHERN INDIGENOUS PEOPLE

By: Sanjana Patel • 2021

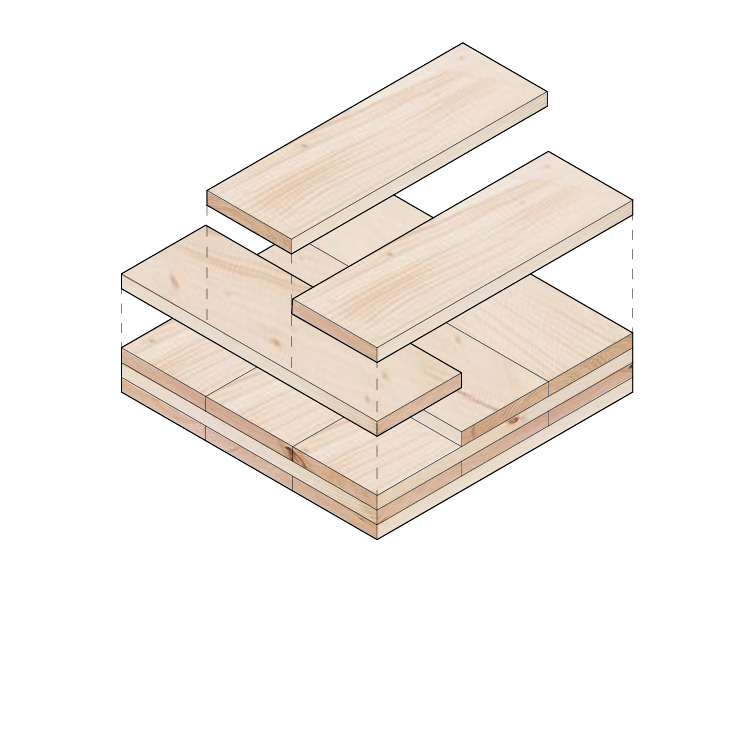

Nest is a home designed for Pikangikum residents in Northern Ontario, assembled as a kit of parts that can be configured by the user. Its layered triangular form is inspired by the merging of two conical wigwams. At the intersection, there is a communal space representing the hearth around which different generations of the same family come together. The shingled, modular envelope system makes up diagonal planes that become both roof and wall, recalling the construction method of early wigwams which used spruce boughs traditionally and then incorporated canvas after colonial settlement. The section can be extended in two directions. In its most compact form, it is a hunting cabin for a small family. In its largest form, a house for 8 people. The structure is made up of modules that can be assembled by teams of people without heavy machinery. LVL beams and columns are machined to snap together and are 3.5m at longest so that they can be lifted. Using this form of assembly, the house can be reconfigured to expand or shrink easily as per a family’s needs.

IDENTIFYING MASS TIMBER RESEARCH PRIORITIES, BARRIERS TO ADOPTION AND ENGINEERING, PROCUREMENT AND CONSTRUCTION CHALLENGES IN CANADA

By: Taha Syed • 2020

Mass timber construction in Canada is in the spotlight and emerging as a sustainable building system that offers an opportunity to optimize the value of every tree harvested and to revitalize a declining forest industry, while providing climate mitigation solutions. Little research has been conducted, however, to identify the mass timber research priorities of end users, barriers to adoption and engineering, procurement and construction challenges in Canada. This study helps bridge these gaps. The study also created an interactive, three-dimensional GIS map displaying mass timber projects across North America, as an attempt to offer a helpful tool to practitioners, researchers and students, and fill a gap in existing knowledge sharing.